Currency

December 10, 2017

Welding is the most economical, efficient and common way to permanently join metals in industry today. When welded, two or more pieces of similar metals are fused together by the use of a filler metal, heat, pressure or both to form a strong joint. Once completed, the welded joint is as strong as or stronger than the pieces from which the joint is formed. There are more than 100 different ways to weld metals together. With so many different ways to weld, types of metals, and filler materials comes many hazards such as flying particles, harmful dust, smoke, fumes, heat and light radiation.

According to the Bureau of Labor Statistics (BLS), in 2014 there were approximately 400,000 welders in the United States with a projected growth rate of 4.4 percent for the next ten years. With that number of welders and number of hazards associated with welding, the BLS has determined the rate of injuries and illnesses is higher than the national average.

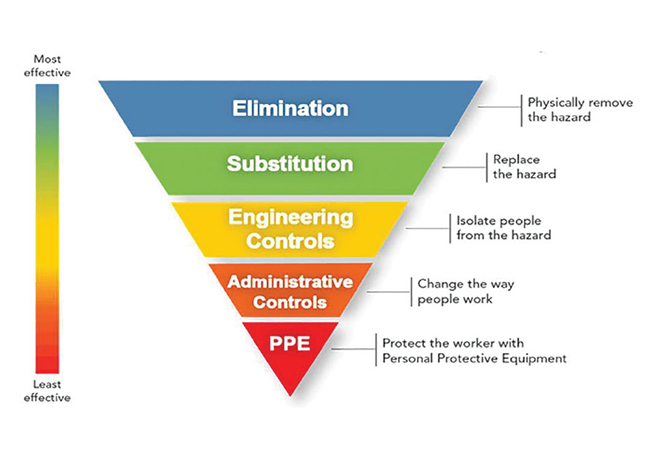

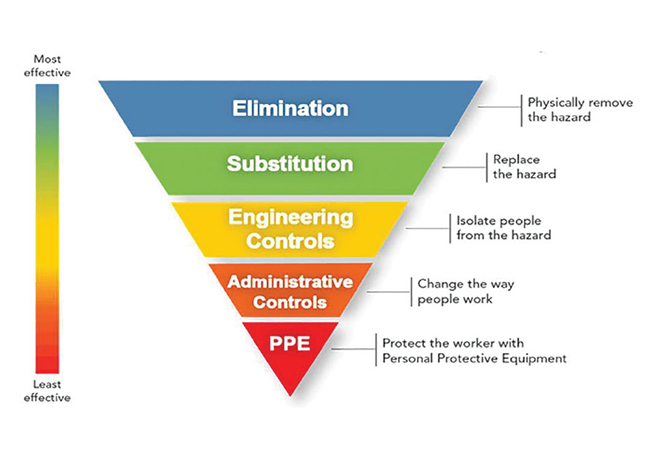

According to OSHA, the best way to reduce the risk of injury and illness in the welding profession is to enact the philosophy of the hierarchy of controls. The hierarchy of controls is a widely accepted concept promoted by numerous safety organizations, and supported by OSHA. It is a way of controlling hazards in a preferred order from most effective to least effective.

According to OSHA, welding is classified into two groups: fusion (heat alone) or pressure (heat and pressure) to join two pieces together. OSHA further breaks fusion welding into three types:

Pressure welding usually involves heating the surfaces to a plastic state and then forcing the metals together.

All types of welding produce hazards. The most common hazard is welding fumes. Welding fumes contain a variety of metals, including but not limited to aluminum, arsenic, beryllium, lead and manganese along with several other gases. Having an awareness of the most common welding hazards helps to target safety training to proactively avoid an injury/illness.

Thermal burn/h1> – The nature of welding involves extreme temperatures that require controls to be in place to prevent burns to the skin. This could be present in the form of sparks and spatter or direct contact with the welded surface.

According to the Bureau of Labor Statistics (BLS), in 2014 there were approximately 400,000 welders in the United States with a projected growth rate of 4.4 percent for the next ten years. With that number of welders and number of hazards associated with welding, the BLS has determined the rate of injuries and illnesses is higher than the national average.

According to OSHA, the best way to reduce the risk of injury and illness in the welding profession is to enact the philosophy of the hierarchy of controls. The hierarchy of controls is a widely accepted concept promoted by numerous safety organizations, and supported by OSHA. It is a way of controlling hazards in a preferred order from most effective to least effective.

Types of welding

According to OSHA, welding is classified into two groups: fusion (heat alone) or pressure (heat and pressure) to join two pieces together. OSHA further breaks fusion welding into three types:

1. Electric arc

– Employs an electric arc to melt the base metals and filler metals and can be further divided into type based on amount of fumes produced (listed least to most): Flux Core Arc Welding (FCAW); Shielded Metal Arc Welding (SMAW); Gas Metal Arc Welding / Metal Inert Gas (GMAW / MIG); Gas Tungsten Arc Welding / Tungsten Inert Gas (GTAW / TIG)2. Gas

– Employs a flame from burning a gas (usually acetylene) to melt the base metal at the joint to be welded.3. Thermit

– Employs a chemical reaction to produce intense heat instead of using gas fuel or electric current.Pressure welding usually involves heating the surfaces to a plastic state and then forcing the metals together.

Welding hazards

All types of welding produce hazards. The most common hazard is welding fumes. Welding fumes contain a variety of metals, including but not limited to aluminum, arsenic, beryllium, lead and manganese along with several other gases. Having an awareness of the most common welding hazards helps to target safety training to proactively avoid an injury/illness.