Currency

December 10, 2017

Falling from height is one of the leading causes of work-related injuries and death. In fact, the U.S. Bureau of Labor Statistics documents nearly 750 fall-related fatalities a year and another 300,000 nonfatal falls requiring at least one day away from work. More surprising than even that? Every single fall is 100-percent preventable.

While OSHA mandates worker safety protocols in an attempt to reduce incidences — and has done a good job of updating the protocols to address fall protection on fixed ladders, there’s much more that industrial and construction employers can do to eliminate the hazards that lead to fall-related accidents and fatalities.

Of particular note is the recently published ANSI/ASSE Z359.16-2016 Safety Requirements for Climbing Ladder Fall Arrest Systems or CLFAS.

Although considered voluntary, the ANSI/ASSE Z59.16 standard was developed with the intention of helping “every employer whose operations fall within the scope and purpose of the standard adopt the guidelines and requirements detailed in the standard,” which were developed by the American Society of Safety Engineers Accredited Standards Committee.

Approved Nov. 2, 2016 and published February, 2017, ANSI/ASSE Z359.16 is the newest standard for CLFAS, and has an effective date within 180 days of the standard’s publication date, which would’ve been this past August.

The new standard “establishes requirements for the performance, design, marking, qualification testing, instructions for use, inspection, maintenance, storage and removal from service of vertically oriented Climbing Ladder Fall Arrest Systems (CLFAS) consisting of flexible and rigid carriers with multiple attachment points and associated carrier sleeves for users within the capacity range of 130 to 310 pounds (59 to 141kg).”

The standard also addresses basic fall safety principles such as hazard survey, hazard elimination and control, education and training, and reactive accident investigation. Visit www.asse.org for the full fall protection code.

All employers need to take ANSI/ASSE standards very seriously — and ANSI/ASSE Z359.16 is no exception.

The purpose of this article is to help employers, and occupational and safety health professionals, understand that CLFAS are the bedrock of at-height personal safety.

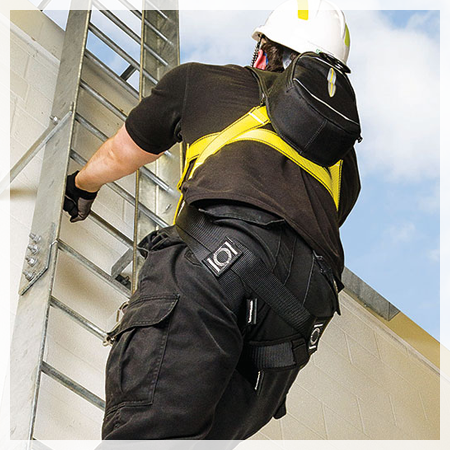

Make no mistake. Climbing is dangerous work. Which is why employers must incorporate a specialized fall protection program into their core safety program, along with personal protective equipment labeled to the latest ANSI requirement.

It’s important to ensure all CLFAS products, including energy-absorbing components, full body harnesses, and connectors, are designed, manufactured, and compliant with ANSI/ASSE Z359.16 standards.

Take for example vertical lifeline cable systems and cable grabs. These are specifically designed to provide ladder fall protection when climbing or descending ladders or vertical structures up to 300 feet in height.

For construction, as well as in its new promulgated Subpart D, General Industry standard, OSHA requires fall protection on fixed ladders at 24 feet and vertical lifeline (VLL) offer the best protection instead of cage/well and self-retracting lifeline (SRL).

While OSHA is no longer actively encouraging the use of cages, and new ones are not being installed, there is no mandate to replace them on existing ladders at this time. (See below for further details.)

Per OSHA, for fixed ladders that extend more than 24 feet above a lower level, employers must ensure the following:

** Each existing fixed ladder installed before Nov. 19, 2018, must be equipped with a personal fall arrest system, ladder safety system, cage, or well;

** Each new fixed ladder installed on and after Nov. 19, 2018, must be equipped with a personal fall arrest system or a ladder safety system;

** Replacement fixed ladders, cages, or wells (or any portion or section), require installation of a personal fall arrest system or ladder safety system in — at a minimum — of that section of the fixed ladder, cage, or well where the replacement is located; and

** On and after Nov. 18, 2036, all fixed ladders must be equipped with a personal fall arrest system or a ladder safety system. While everyone should determine which equipment is best for the job, the environment, and the safety of the worker at height, below are three steps you can take right now to help ensure that you’re taking a proactive approach toward 100-percent fall prevention protection.

1. Make a thorough assessment of all fall hazards, including sides and edges, hoist areas, and skylights.

2. Create a list of those hazards and schedule, at a minimum, an annual review.

3. Document and implement appropriate protective measures, including procedures, protocols, equipment, and worker training.

OSHA standards vs. ANSI best practices

While OSHA mandates worker safety protocols in an attempt to reduce incidences — and has done a good job of updating the protocols to address fall protection on fixed ladders, there’s much more that industrial and construction employers can do to eliminate the hazards that lead to fall-related accidents and fatalities.

Of particular note is the recently published ANSI/ASSE Z359.16-2016 Safety Requirements for Climbing Ladder Fall Arrest Systems or CLFAS.

A best practice: Adopt the consensus standard

Although considered voluntary, the ANSI/ASSE Z59.16 standard was developed with the intention of helping “every employer whose operations fall within the scope and purpose of the standard adopt the guidelines and requirements detailed in the standard,” which were developed by the American Society of Safety Engineers Accredited Standards Committee.

Approved Nov. 2, 2016 and published February, 2017, ANSI/ASSE Z359.16 is the newest standard for CLFAS, and has an effective date within 180 days of the standard’s publication date, which would’ve been this past August.

The new standard “establishes requirements for the performance, design, marking, qualification testing, instructions for use, inspection, maintenance, storage and removal from service of vertically oriented Climbing Ladder Fall Arrest Systems (CLFAS) consisting of flexible and rigid carriers with multiple attachment points and associated carrier sleeves for users within the capacity range of 130 to 310 pounds (59 to 141kg).”

The standard also addresses basic fall safety principles such as hazard survey, hazard elimination and control, education and training, and reactive accident investigation. Visit www.asse.org for the full fall protection code.

All employers need to take ANSI/ASSE standards very seriously — and ANSI/ASSE Z359.16 is no exception.

Climbing ladder fall arrest systems (CFLAS)

The purpose of this article is to help employers, and occupational and safety health professionals, understand that CLFAS are the bedrock of at-height personal safety.

Make no mistake. Climbing is dangerous work. Which is why employers must incorporate a specialized fall protection program into their core safety program, along with personal protective equipment labeled to the latest ANSI requirement.

It’s important to ensure all CLFAS products, including energy-absorbing components, full body harnesses, and connectors, are designed, manufactured, and compliant with ANSI/ASSE Z359.16 standards.

Take for example vertical lifeline cable systems and cable grabs. These are specifically designed to provide ladder fall protection when climbing or descending ladders or vertical structures up to 300 feet in height.

For construction, as well as in its new promulgated Subpart D, General Industry standard, OSHA requires fall protection on fixed ladders at 24 feet and vertical lifeline (VLL) offer the best protection instead of cage/well and self-retracting lifeline (SRL).

While OSHA is no longer actively encouraging the use of cages, and new ones are not being installed, there is no mandate to replace them on existing ladders at this time. (See below for further details.)

Per OSHA, for fixed ladders that extend more than 24 feet above a lower level, employers must ensure the following:

** Each existing fixed ladder installed before Nov. 19, 2018, must be equipped with a personal fall arrest system, ladder safety system, cage, or well;

** Each new fixed ladder installed on and after Nov. 19, 2018, must be equipped with a personal fall arrest system or a ladder safety system;

** Replacement fixed ladders, cages, or wells (or any portion or section), require installation of a personal fall arrest system or ladder safety system in — at a minimum — of that section of the fixed ladder, cage, or well where the replacement is located; and

** On and after Nov. 18, 2036, all fixed ladders must be equipped with a personal fall arrest system or a ladder safety system. While everyone should determine which equipment is best for the job, the environment, and the safety of the worker at height, below are three steps you can take right now to help ensure that you’re taking a proactive approach toward 100-percent fall prevention protection.

Action steps

1. Make a thorough assessment of all fall hazards, including sides and edges, hoist areas, and skylights.

2. Create a list of those hazards and schedule, at a minimum, an annual review.

3. Document and implement appropriate protective measures, including procedures, protocols, equipment, and worker training.