Currency

August 20, 2017

Hand safety starts with knowing the risks of injury in the workplace, and how to prevent them. Here’s our quick guide to hand protection.

Why are hand injuries so serious?

Work-related hand injuries are one of the main reasons workers end up in the emergency room. Whether it’s damage to the nerves in your fingers and hands, losing a finger, a burn to the skin or an allergic reaction, injury to your hands can negatively impact the quality of your work and your ability to be productive. Worst case scenario, it can end your career and detract from your overall quality of life.

How are hand injuries caused?

Think about it like this: how many times have you touched a surface only to discover it’s hot? Felt pain in your hand because of how you gripped a tool or twisted your wrist while working? Come close to having your hand or finger caught or crushed by the tools you were using? How many times have you come into skin contact with chemicals or caustic substances?

If you can think of even one time any of these scenarios took place, it’s one time too many – you were lucky to walk away uninjured and you might not be as fortunate the next time.

Top hazards for your hands in the workplace

-Punctures, cuts or lacerations caused by contact with sharp, spiked or jagged edges on equipment, tools or materials.

-Crushes, fractures or amputations caused by contact with gears, belts, wheels and rollers, falling objects, and rings, gloves or clothing getting caught and putting your hand in harm’s way.

-Strains, sprains, and other musculoskeletal injuries caused by using the wrong tool for the job, or one that is too big, small or heavy for your hand.

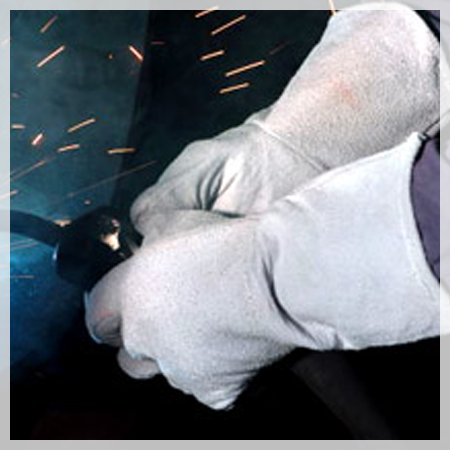

-Burns caused by direct contact with a hot surface or a chemical.

-Dermatitis and other skin disorders caused by direct contact with chemicals in products and materials.

-Preventing hand injuries isn’t hard work

To keep your hands safe from injury, it’s important to establish and enforce safe working practices in your workplace. Ensure that you use the equipment and appropriate gloves provided in your workplace. Gloves and safety procedures are ineffective if they’re not used or followed. Be mindful of the job and consider tasks, equipment and materials that could potentially create the risk of injury or put your skin in contact with chemicals.

Safety tips that make sense

-Distraction is the enemy: stay alert and focused on keeping your hands safe while working, not just at the start of work or a task.

-Don’t ignore safety: keep the guards on machinery and power tools in place at all times – do not remove or reposition them.

-The right tool for the job, used correctly: use only the appropriate tools and equipment designed for the work that needs to be performed and use them as per manufacturer instructions.

-Don’t get handsy with danger: do not put your hands or fingers near the moving parts of a power tool or equipment and be sure to switch off machinery, equipment and power tools before you attempt replacing, cleaning or repairing parts

-Get to know your tools: identify safety features on tools and equipment before you use them, such as emergency off switches.

-Run a quick visual safety check: inspect tools and equipment to make sure they are in proper working order before starting a task.

-Avoid the edge: keep your hands and fingers away from sharp edges (blades, protruding nails, etc.) and never cut toward the palm of your hand.

-Size matters: select hand tools that are ergonomic for your hand (this includes: the right size, lowest weight, and features like grips, anti-vibration handles, handles angles that do not require you to work with your wrist bent).

-Leave fashion in the locker room: take off all rings, jewelry or loose articles of clothing that could get caught on a moving object.

-Don’t forget to glove up: choose and wear the correct gloves that fit your hand. Make sure they’re the right gloves for the work being performed – not all gloves protect against all hazards.