Currency

March 28, 2022

The electrical safety PPE industry landscape is evolving rapidly as workplace safety and wellbeing take centre stage. Over the past decade, there have been countless instances of accidents and injuries to electrical workers. To reduce the risk of such incidents, respective governments, regulatory bodies, and private organisations are taking active measures.

The Electrical Safety Foundation International (ESFI) reports that more than 166 electrical fatalities were recorded in the U.S. in 2019, the highest since 2011. As part of the National Electrical Safety Month, ESFI rolled out its annual effort in May to reduce the number of electricity-related injuries, fatalities, and property losses. The theme for this year’s campaign is Connected to Safety, which is aimed at educating the workforce about solar energy and temporary power related safety precautions. The initiative also aims to help businesses prepare the workforce for electric vehicle charging infrastructure.

“the global electrical safety PPE market size is predicted to reach US$21.5 billion by the end of 2027”

In addition to electrical and automotive applications, PPE demand is expanding across construction, mining, machinery, and oil and gas sectors. With changing regulatory scenarios pertaining to electrical worker safety, the global electrical safety PPE market size is predicted to reach US$21.5 billion by the end of 20271. Explained below are some key factors influencing the demand for different types of personal protective equipment used in electrical applications.

Head protection gear is among the most important lines of defence against electrical hazards in numerous applications including power line maintenance, mining, construction, and others. It protects workers and linemen from falling or flying objects, electrical shocks, spills, drips, and splashes. Strict regulations mandating their use will boost head protection demand in the electrical safety PPE industry.

As per the Occupational Safety and Health Administration (OSHA), employers must enforce head protection for workers whose heads may come into contact with electrical hazards. OSHA recommends that head protection products such as hard hats, protective hoods, and arc rated hoods should be kept free of paints and certain cleaning agents that can impact their electrical resistance and durability.

Eye and face protection are critically important for electrical workers and linemen to prevent hazards such as shocks, burns, and exposure to ultraviolet radiation. Face shields and safety glasses help protect workers against flying objects and fragments that can cause eye or face damage.

Eye injuries are highly common in industrial environments, and many of those are preventable. The National Institute for Occupational Safety and Health (NIOSH) reports that nearly 2,000 eye injuries requiring medical attention take place in the U.S. each year. NIOSH also reports that 90% of these injuries can be prevented using eye and face protection

The introduction of strict government regulations to reduce the burden of eye injuries will boost the demand for eye and face protection equipment in the electrical safety PPE industry.

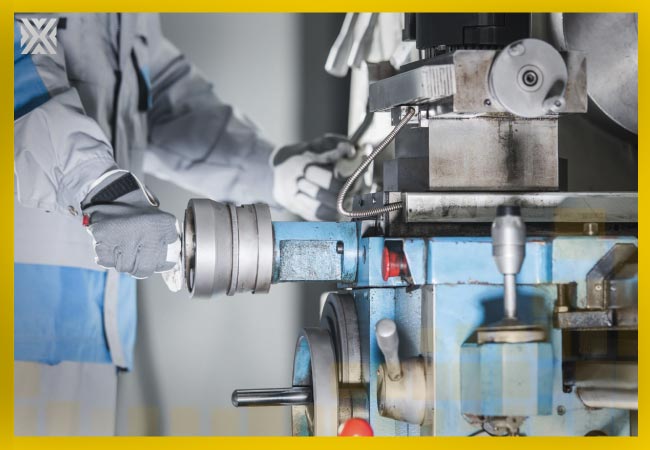

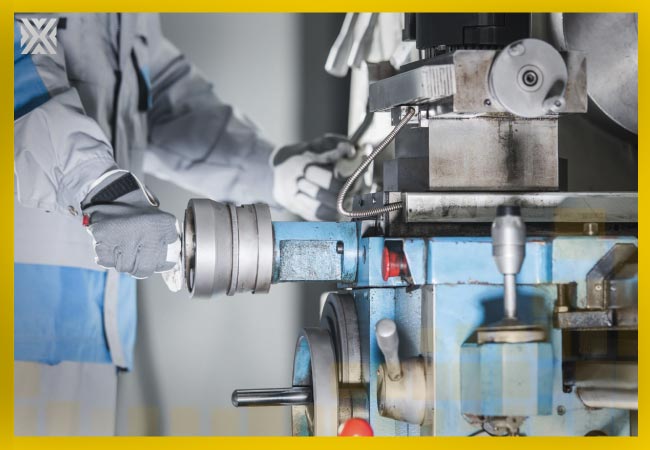

When it comes to workers facing electrical risks, most injuries occur when proper hand protection is not employed. Fire-resistant apparel such as insulating rubber gloves, insulating rubber sleeves, and leather protective gloves play an important role in protecting workers, not just from shocks but also against cuts, tears, and punctures.

OSHA recommends that appropriate gloves and other protective equipment must be used by workers to protect themselves from cuts burns, shocks, absorption of chemicals, and amputation.

Speaking of fire-resistant apparel, arc rated clothing has gained much attention in the electrical industry landscape over the past few years. This is mainly due to the rise in arc flash events that can result in electrical explosions. According to the Bureau of Labor Statistics, about five to 10 arc fault incidents occur per day in the U.S. Due to this reason, strict regulations are being undertaken.

The Electrical Safety Foundation International (ESFI) reports that more than 166 electrical fatalities were recorded in the U.S. in 2019, the highest since 2011. As part of the National Electrical Safety Month, ESFI rolled out its annual effort in May to reduce the number of electricity-related injuries, fatalities, and property losses. The theme for this year’s campaign is Connected to Safety, which is aimed at educating the workforce about solar energy and temporary power related safety precautions. The initiative also aims to help businesses prepare the workforce for electric vehicle charging infrastructure.

“the global electrical safety PPE market size is predicted to reach US$21.5 billion by the end of 2027”

In addition to electrical and automotive applications, PPE demand is expanding across construction, mining, machinery, and oil and gas sectors. With changing regulatory scenarios pertaining to electrical worker safety, the global electrical safety PPE market size is predicted to reach US$21.5 billion by the end of 20271. Explained below are some key factors influencing the demand for different types of personal protective equipment used in electrical applications.

Head Protection

Head protection gear is among the most important lines of defence against electrical hazards in numerous applications including power line maintenance, mining, construction, and others. It protects workers and linemen from falling or flying objects, electrical shocks, spills, drips, and splashes. Strict regulations mandating their use will boost head protection demand in the electrical safety PPE industry.

As per the Occupational Safety and Health Administration (OSHA), employers must enforce head protection for workers whose heads may come into contact with electrical hazards. OSHA recommends that head protection products such as hard hats, protective hoods, and arc rated hoods should be kept free of paints and certain cleaning agents that can impact their electrical resistance and durability.

Eye and Face Protection

Eye and face protection are critically important for electrical workers and linemen to prevent hazards such as shocks, burns, and exposure to ultraviolet radiation. Face shields and safety glasses help protect workers against flying objects and fragments that can cause eye or face damage.

Eye injuries are highly common in industrial environments, and many of those are preventable. The National Institute for Occupational Safety and Health (NIOSH) reports that nearly 2,000 eye injuries requiring medical attention take place in the U.S. each year. NIOSH also reports that 90% of these injuries can be prevented using eye and face protection

The introduction of strict government regulations to reduce the burden of eye injuries will boost the demand for eye and face protection equipment in the electrical safety PPE industry.

Hand Protection

When it comes to workers facing electrical risks, most injuries occur when proper hand protection is not employed. Fire-resistant apparel such as insulating rubber gloves, insulating rubber sleeves, and leather protective gloves play an important role in protecting workers, not just from shocks but also against cuts, tears, and punctures.

OSHA recommends that appropriate gloves and other protective equipment must be used by workers to protect themselves from cuts burns, shocks, absorption of chemicals, and amputation.

Arc Rated Clothing

Speaking of fire-resistant apparel, arc rated clothing has gained much attention in the electrical industry landscape over the past few years. This is mainly due to the rise in arc flash events that can result in electrical explosions. According to the Bureau of Labor Statistics, about five to 10 arc fault incidents occur per day in the U.S. Due to this reason, strict regulations are being undertaken.