Currency

November 24, 2019

What do you think are the most common causes of non-fatal workplace injuries in the UK? I’ll tell you: it’s slips, trips and falls on the same level. Statistics show that around 100,000 reported injuries are attributable to slips, trips and falls every year. That’s bad news for the workers involved, obviously, but it’s also not great for businesses or the economy, either. Yet workplace slips are preventable.

Equipping employees with the footwear that performs best in their particular working environment can make all the difference. Here are two real-world examples from the Health and Safety Executive’s (HSE) experience.

In the first example, a utilities company had reported 74 long term slip/trip injuries among their door-to-door sales team (that’s those folk who come around asking you to change your energy provider). This became such a problem that they stood their workers down during the worst of the winter weather. Following the utility company’s introduction of new occupational footwear, slip-related injuries were reduced by almost 100%. Since the new footwear performed better in the various conditions faced daily by the salespeople, the sales team could then work safely in all weathers.

Things didn’t work out quite as well for the subject of the second example.

“equipping employees with the footwear that performs best in their particular working environment can make all the difference”

Aiming to improve worker health and safety, an oil company changed its occupational footwear to a design that offered greater ankle support. Inadvertently, however, they opted for a safety boot that provided inadequate slip resistance. Despite the good intentions of their action, long term injuries resulting from workplace slips increased significantly.

These examples highlight not only the contribution that providing the right footwear can make to improving health and safety at work, but also the need for reliable, accessible information and specifications for occupational footwear.

Slips happen when a pedestrian needs more friction than is offered by the combination of their footwear, the flooring they are walking on and any contaminant between the two, be that water, oil or ice, for example. This is most common during the heel strike phase of gait and often results in a backward fall.

The biggest challenges when trying to prevent slips in the workplace are knowing where to find reliable information on flooring, understanding the ins and outs of cleaning, and knowing how to select appropriate footwear. Understanding the science behind slips makes it easier to identify the true cause of a fall and prevent future incidents.

Slip resistant footwear can be a key control measure in preventing slips. This is particularly true in industries where safety footwear is a requirement, since protective footwear which also offers excellent slip resistance will protect the user from more than one hazard.

Similarly, this applies to peripatetic workers who frequently walk significant distances as part of their work, increasing their exposure to hazardous conditions. They are often outdoors or on other people’s premises where there is no control over the floor surfaces they are walking on or the contamination on the floor. In these conditions well specified slip resistant footwear may be the only control available to prevent slips.

“understanding the science behind slips makes it easier to identify the true cause of a fall and prevent future incidents”

Not all shoes are equal

Think all safety shoes provide great slip resistance? Think again.

Given the sheer numbers of sliprelated injuries at work, you could be forgiven for thinking that robust slip resistance would be a baseline feature of any safety footwear. Unfortunately, this is not the case: research carried out by HSE shows that slip-resistance varies considerably from shoe to shoe, with some types of outsole providing far greater slip resistance than others. In fact, some of the outsoles tested by HSE in conditions similar to many regular working environments offered disappointingly poor levels of slip resistance.

This poses a problem for anyone whose role involves purchasing safety footwear for an organisation. If there’s no obvious guidance as to a shoe or boot’s level of slip resistance, a purchaser might inadvertently buy footwear that actually increases the risk of slip accidents among employees.

It’s for this reason that HSE’s slips, trips and falls specialists recognised the need for a new and unambiguous means of testing and rating the slip resistance of occupational footwear.

The vast majority of occupational footwear is sold with evidence of slip resistance from the European standard test. The ‘highest’ classification that results from this standard is ‘SRC’. This means that the tested footwear has achieved a minimum level of slip resistance on a smooth steel surface lubricated with a viscous liquid to replicate oils, and a textured ceramic surface lubricated with an aqueous detergent solution.

Based on the findings of the European standard test, you might think that easily identifying the slip resistance of an item of footwear is simply a case of choosing the appropriate classification, SRA or SRC. Unfortunately, it’s not that straightforward.

Concerns have been raised by the scientific community that the European standard test does not sufficiently replicate the critical point of the walking step at which grip is lost when you slip. Work carried out in the laboratory of the University of Southern California (Blanchette and Powers, 2014) calls into question the overall validity of the test because of its inability to predict slip potential.

HSE estimates that around 8,500 reportable slipping accidents per year occur at work, in safety footwear classified as either SRA or SRC.

At best then, the European standard can be usefully viewed as a minimum level of slip resistance required to bring footwear to the market. In working environments where health and safety professionals are concerned about slips and would like footwear to be a control measure, the standard classifications alone won’t tell you everything you need to know.

HSE’s solution to this issue was to devise a more rigorous method with which to test and rate the slip resistance of occupational footwear: enter the GRIP scheme.

Next up, is everything you ever wanted to know about HSE’s GRIP scheme, but were too afraid to ask.

As the UK’s health and safety regulator, HSE fundamentally believes that every worker has the right to go home healthy at the end of each day. Since slips, trips and falls are the most common cause of workplace injury, we’ve invested significant time and resource in understanding the science and identifying their causes.

As a consequence, HSE’s GRIP scheme was launched in June 2014 to provide a better way for occupational footwear manufacturers to help customers select footwear based on their slip resistance needs. Manufacturer participation in the GRIP scheme is entirely voluntary. The benefit to footwear buyers is that the GRIP scheme provides free, reliable information about the slip performance of different types of footwear. This enables a better informed purchasing decision that can reduce workplace slip injuries and their associated costs.

So how does HSE test and rate the slip resistance of occupational footwear? Over a number of years, HSE’s slips, trips and falls specialists have refined an already proven ‘ramp test’ methodology as well as developing an all new mechanical test, known as the HSE Simulated Slip Test (SST). These test methods have been designed to replicate real-world walking dynamics and pedestrian friction requirements.

Footwear is tested on a slippery wet ceramic tile that is deliberately challenging for the footwear, in order to find out what happens when the limits of grip are really pushed. The Ramp Test The ramp used in GRIP testing consists of an adjustable platform upon which the test flooring, in this case the ceramic tiling, is positioned. A fall arrest device is attached to an overhead frame in order to protect the operator who is testing the footwear. The operator walks back and forth on the test flooring, gradually increasing the angle of inclination of the platform. Eventually, the operator will generate a number of angles at which slipping is unavoidable. At this point, a second operator will repeat the testing process from the start. In order to ensure reproducibility of the results, three different pairs of the same footwear in total are used to generate the final GRIP rating.

Equipping employees with the footwear that performs best in their particular working environment can make all the difference. Here are two real-world examples from the Health and Safety Executive’s (HSE) experience.

In the first example, a utilities company had reported 74 long term slip/trip injuries among their door-to-door sales team (that’s those folk who come around asking you to change your energy provider). This became such a problem that they stood their workers down during the worst of the winter weather. Following the utility company’s introduction of new occupational footwear, slip-related injuries were reduced by almost 100%. Since the new footwear performed better in the various conditions faced daily by the salespeople, the sales team could then work safely in all weathers.

Things didn’t work out quite as well for the subject of the second example.

“equipping employees with the footwear that performs best in their particular working environment can make all the difference”

Aiming to improve worker health and safety, an oil company changed its occupational footwear to a design that offered greater ankle support. Inadvertently, however, they opted for a safety boot that provided inadequate slip resistance. Despite the good intentions of their action, long term injuries resulting from workplace slips increased significantly.

These examples highlight not only the contribution that providing the right footwear can make to improving health and safety at work, but also the need for reliable, accessible information and specifications for occupational footwear.

Why slips happen

Slips happen when a pedestrian needs more friction than is offered by the combination of their footwear, the flooring they are walking on and any contaminant between the two, be that water, oil or ice, for example. This is most common during the heel strike phase of gait and often results in a backward fall.

The biggest challenges when trying to prevent slips in the workplace are knowing where to find reliable information on flooring, understanding the ins and outs of cleaning, and knowing how to select appropriate footwear. Understanding the science behind slips makes it easier to identify the true cause of a fall and prevent future incidents.

Slip resistant footwear can be a key control measure in preventing slips. This is particularly true in industries where safety footwear is a requirement, since protective footwear which also offers excellent slip resistance will protect the user from more than one hazard.

Similarly, this applies to peripatetic workers who frequently walk significant distances as part of their work, increasing their exposure to hazardous conditions. They are often outdoors or on other people’s premises where there is no control over the floor surfaces they are walking on or the contamination on the floor. In these conditions well specified slip resistant footwear may be the only control available to prevent slips.

“understanding the science behind slips makes it easier to identify the true cause of a fall and prevent future incidents”

Not all shoes are equal

Think all safety shoes provide great slip resistance? Think again.

Given the sheer numbers of sliprelated injuries at work, you could be forgiven for thinking that robust slip resistance would be a baseline feature of any safety footwear. Unfortunately, this is not the case: research carried out by HSE shows that slip-resistance varies considerably from shoe to shoe, with some types of outsole providing far greater slip resistance than others. In fact, some of the outsoles tested by HSE in conditions similar to many regular working environments offered disappointingly poor levels of slip resistance.

This poses a problem for anyone whose role involves purchasing safety footwear for an organisation. If there’s no obvious guidance as to a shoe or boot’s level of slip resistance, a purchaser might inadvertently buy footwear that actually increases the risk of slip accidents among employees.

It’s for this reason that HSE’s slips, trips and falls specialists recognised the need for a new and unambiguous means of testing and rating the slip resistance of occupational footwear.

What about SRA and SRC ratings?

The vast majority of occupational footwear is sold with evidence of slip resistance from the European standard test. The ‘highest’ classification that results from this standard is ‘SRC’. This means that the tested footwear has achieved a minimum level of slip resistance on a smooth steel surface lubricated with a viscous liquid to replicate oils, and a textured ceramic surface lubricated with an aqueous detergent solution.

Based on the findings of the European standard test, you might think that easily identifying the slip resistance of an item of footwear is simply a case of choosing the appropriate classification, SRA or SRC. Unfortunately, it’s not that straightforward.

Concerns have been raised by the scientific community that the European standard test does not sufficiently replicate the critical point of the walking step at which grip is lost when you slip. Work carried out in the laboratory of the University of Southern California (Blanchette and Powers, 2014) calls into question the overall validity of the test because of its inability to predict slip potential.

HSE estimates that around 8,500 reportable slipping accidents per year occur at work, in safety footwear classified as either SRA or SRC.

At best then, the European standard can be usefully viewed as a minimum level of slip resistance required to bring footwear to the market. In working environments where health and safety professionals are concerned about slips and would like footwear to be a control measure, the standard classifications alone won’t tell you everything you need to know.

HSE’s solution to this issue was to devise a more rigorous method with which to test and rate the slip resistance of occupational footwear: enter the GRIP scheme.

The GRIP scheme

Next up, is everything you ever wanted to know about HSE’s GRIP scheme, but were too afraid to ask.

As the UK’s health and safety regulator, HSE fundamentally believes that every worker has the right to go home healthy at the end of each day. Since slips, trips and falls are the most common cause of workplace injury, we’ve invested significant time and resource in understanding the science and identifying their causes.

As a consequence, HSE’s GRIP scheme was launched in June 2014 to provide a better way for occupational footwear manufacturers to help customers select footwear based on their slip resistance needs. Manufacturer participation in the GRIP scheme is entirely voluntary. The benefit to footwear buyers is that the GRIP scheme provides free, reliable information about the slip performance of different types of footwear. This enables a better informed purchasing decision that can reduce workplace slip injuries and their associated costs.

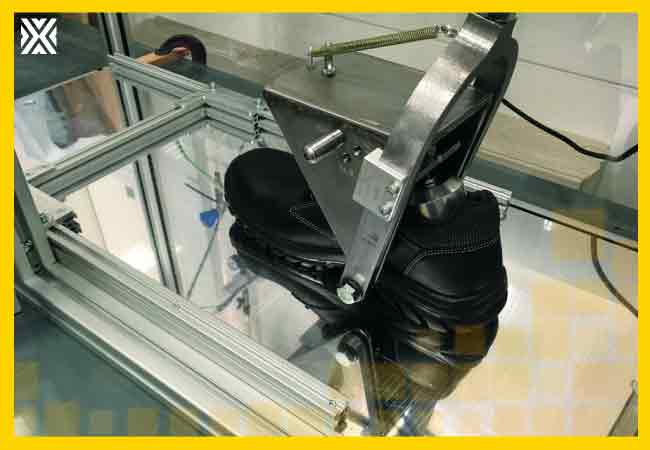

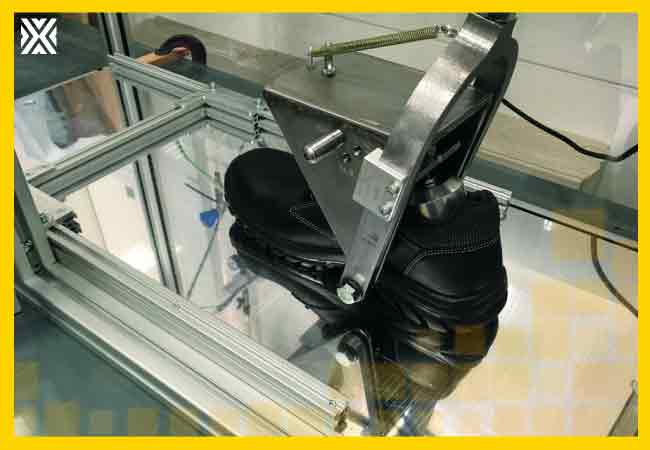

So how does HSE test and rate the slip resistance of occupational footwear? Over a number of years, HSE’s slips, trips and falls specialists have refined an already proven ‘ramp test’ methodology as well as developing an all new mechanical test, known as the HSE Simulated Slip Test (SST). These test methods have been designed to replicate real-world walking dynamics and pedestrian friction requirements.

Footwear is tested on a slippery wet ceramic tile that is deliberately challenging for the footwear, in order to find out what happens when the limits of grip are really pushed. The Ramp Test The ramp used in GRIP testing consists of an adjustable platform upon which the test flooring, in this case the ceramic tiling, is positioned. A fall arrest device is attached to an overhead frame in order to protect the operator who is testing the footwear. The operator walks back and forth on the test flooring, gradually increasing the angle of inclination of the platform. Eventually, the operator will generate a number of angles at which slipping is unavoidable. At this point, a second operator will repeat the testing process from the start. In order to ensure reproducibility of the results, three different pairs of the same footwear in total are used to generate the final GRIP rating.