Currency

June 15, 2019

Excessive noise is prevalent across industries. From manufacturing to construction, agriculture to oil and gas, more than 22 million U.S. workers are exposed to hazardous noise each year.1 Wherever unsafe levels of noise exist, employers are responsible for providing hearing protection devices (HPDs) – and where daily exposures average more than 85 dBA, a hearing conservation program is also required. But you’re not alone if you wonder whether your current approach to hearing conservation is netting the results your workers need to preserve their hearing for the long term.

Despite the superior quality of today’s HPDs, noise is still robbing workers’ sense of hearing at an alarming rate. The CDC reports that 24% of hearing loss among workers is caused by occupational noise exposures.2 Furthermore, 34% of noise-exposed workers report not wearing hearing protection.3

The costs of noncompliance, improper use and resulting hearing loss are huge. Employers pay $1.5 million in penalties annually for not protecting workers from noise4, and more than $242 million is spent on workers’ compensation for hearing loss disability each year.5

With new technologies, hearing conservation programs are undergoing much needed modernization. Near-real-time metrics using leading – rather than lagging – indicators enable employers to measure and adjust the efficacy of workers’ hearing protection any time, any place, and on a personal level.

This article looks at how embracing small changes in your approach can help any organization personalize its hearing conservation program – and net big returns.

Noise-induced hearing loss (NIHL) is the #1 most common permanent and preventable occupational injury.6 Unlike most injuries, it is difficult to tell when an individual has been affected by NIHL because it is painless and progressive. Caused by either continuous or intermittent exposure to sounds ≥85 decibels or by one-time high-intensity impulsive noise exposures, the effects on one’s hearing are irreversible. However, experts agree that occupational NIHL can be reduced – even eliminated – when proper measures are implemented.

OSHA 29 CFR 1910.95 requires employers to measure noise levels and employ engineering and administrative controls to reduce excessive noise levels. Wherever such controls fail to reduce noise to permissible levels, OSHA calls for personal hearing protection devices to be provided and used. Where noise exposures equal or exceed an 8-hour, time-weighted average (TWA) sound level of 85 dBA, a hearing conservation program is also required.

In a traditional hearing conservation program, employers measure noise levels in the facility, offer a variety of HPDs, train workers on proper HPD use, and conduct annual audiometric testing for noise-exposed workers.

A universal challenge that safety managers face, though, is knowing how much protection their employees actually achieve with their earplugs. While noise reduction ratings (NRR) are an estimate of hearing protector performance as measured under optimum laboratory conditions, the attenuation realized by individuals in the field vary – and often fall below the stated attenuation rating.

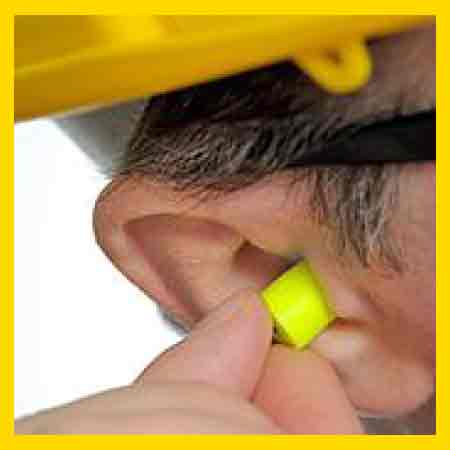

How do you know whether your worker is inserting earplugs in such a way that ensures proper attenuation?

Ear canals are as unique as fingerprints in size and shape; has each worker selected and tested the fit of his or her earplug of choice?

Earplugs are also unique in size, shape, material and insertion techniques; are you offering a broad enough variety to meet workers’ needs?

Given environmental demands like extreme heat, humidity, and grime, are workers consistently wearing earplugs when, where and how they should be?

The reality is, you may not know what level of hearing protection each worker has achieved until you conduct annual audiometric testing. If hearing loss is detected, irreversible damage has occurred and the focus becomes conserving what hearing remains. This reactionary approach relies on lagging indicators, meaning you learn there’s a problem only after hearing loss has occurred. At that point you may make adjustments in worker training or HPD selection, but it’s too late to fix what’s already lost: your workers’ vital sense of hearing.

New technologies allow safety managers to get a clear picture of workers’ actual level of hearing protection before they walk onto the floor. Fit testing is one key aspect to an effective hearing loss prevention strategy. Rather than relying on an earplug’s stated NRR, fit testing provides insight into the HPD’s attenuation as achieved by the individual.

Fit testing is quick, easy, and can be conducted as often as needed: before an individual begins work among noise, during annual audiograms, as part of ongoing worker training, or whenever the safety manager feels an individual needs a refresher.

In-ear exposure monitoring takes hearing loss prevention a step further. By placing a microphone into the ear canal and under the earplug, workers can wear in-ear exposure monitoring devices continuously on the floor. The result is the collection of invaluable real-time data for personal noise exposure. In-ear exposure monitoring moves the dial from guessing a worker’s exposure to knowing their actual exposure.

With leading indicators such as these, safety managers can determine whether the workers’ hearing is protected at the proper level for the noise hazards and, if not, explore steps for improvement such as additional training on how to achieve a proper fit, trying different earplug styles and sizes for personal comfort and attenuation, or making changes within the work environment. This altered approach focuses on preventing hearing loss before it occurs.

A defining aspect of successful hearing loss prevention programs is personalization. One-on-one, face-to-face instruction is proven more effective than videos or reading material for training workers on proper earplug insertion, fit and overall use.7 One-on-one fit testing is also integral to measuring – rather than guessing – the level of attenuation achieved by an individual’s HPDs. In fact, personal fit testing is an OSHA best practice.

In a Best Practice Bulletin by the National Hearing Conservation Association and OSHA, “Studies have suggested that when individuals are involved in the fitting process and receive positive feedback on the proper fit of their earplug, they will be more likely to have a positive attitude about protecting their hearing and will be more apt to use hearing protection correctly and consistently in the workplace. The positive outcome should result in reducing noise-induced hearing loss in the workplace.”8

The best hearing protector is the one that is worn most comfortably by an individual, and is worn correctly 100% of the time when he or she is exposed to noise. Enable the proper selection of earplugs by offering various styles and sizes, monitoring sound exposures and protection levels regularly, and training workers individually on how to achieve a personal fit for the greatest attenuation.

While the hearing protection devices you provide may deliver high NRRs and high quality, noncompliance, improper fit and a reliance on lagging indicators all play a role in America’s ongoing struggle to adequately protect workers’ invaluable sense of hearing. By focusing on leading indicators and taking a personal approach to hearing loss prevention, we can help reduce the staggering number of workers affected by NIHL. That’s a sound solution that workers, their families, friends and employers can all agree on.

Despite the superior quality of today’s HPDs, noise is still robbing workers’ sense of hearing at an alarming rate. The CDC reports that 24% of hearing loss among workers is caused by occupational noise exposures.2 Furthermore, 34% of noise-exposed workers report not wearing hearing protection.3

The costs of noncompliance, improper use and resulting hearing loss are huge. Employers pay $1.5 million in penalties annually for not protecting workers from noise4, and more than $242 million is spent on workers’ compensation for hearing loss disability each year.5

With new technologies, hearing conservation programs are undergoing much needed modernization. Near-real-time metrics using leading – rather than lagging – indicators enable employers to measure and adjust the efficacy of workers’ hearing protection any time, any place, and on a personal level.

This article looks at how embracing small changes in your approach can help any organization personalize its hearing conservation program – and net big returns.

Noise-induced hearing loss

Noise-induced hearing loss (NIHL) is the #1 most common permanent and preventable occupational injury.6 Unlike most injuries, it is difficult to tell when an individual has been affected by NIHL because it is painless and progressive. Caused by either continuous or intermittent exposure to sounds ≥85 decibels or by one-time high-intensity impulsive noise exposures, the effects on one’s hearing are irreversible. However, experts agree that occupational NIHL can be reduced – even eliminated – when proper measures are implemented.

Traditional approach to mitigating NIHL

OSHA 29 CFR 1910.95 requires employers to measure noise levels and employ engineering and administrative controls to reduce excessive noise levels. Wherever such controls fail to reduce noise to permissible levels, OSHA calls for personal hearing protection devices to be provided and used. Where noise exposures equal or exceed an 8-hour, time-weighted average (TWA) sound level of 85 dBA, a hearing conservation program is also required.

In a traditional hearing conservation program, employers measure noise levels in the facility, offer a variety of HPDs, train workers on proper HPD use, and conduct annual audiometric testing for noise-exposed workers.

A universal challenge that safety managers face, though, is knowing how much protection their employees actually achieve with their earplugs. While noise reduction ratings (NRR) are an estimate of hearing protector performance as measured under optimum laboratory conditions, the attenuation realized by individuals in the field vary – and often fall below the stated attenuation rating.

The reality is, you may not know what level of hearing protection each worker has achieved until you conduct annual audiometric testing. If hearing loss is detected, irreversible damage has occurred and the focus becomes conserving what hearing remains. This reactionary approach relies on lagging indicators, meaning you learn there’s a problem only after hearing loss has occurred. At that point you may make adjustments in worker training or HPD selection, but it’s too late to fix what’s already lost: your workers’ vital sense of hearing.

Focus on hearing loss prevention

New technologies allow safety managers to get a clear picture of workers’ actual level of hearing protection before they walk onto the floor. Fit testing is one key aspect to an effective hearing loss prevention strategy. Rather than relying on an earplug’s stated NRR, fit testing provides insight into the HPD’s attenuation as achieved by the individual.

Fit testing is quick, easy, and can be conducted as often as needed: before an individual begins work among noise, during annual audiograms, as part of ongoing worker training, or whenever the safety manager feels an individual needs a refresher.

In-ear exposure monitoring takes hearing loss prevention a step further. By placing a microphone into the ear canal and under the earplug, workers can wear in-ear exposure monitoring devices continuously on the floor. The result is the collection of invaluable real-time data for personal noise exposure. In-ear exposure monitoring moves the dial from guessing a worker’s exposure to knowing their actual exposure.

With leading indicators such as these, safety managers can determine whether the workers’ hearing is protected at the proper level for the noise hazards and, if not, explore steps for improvement such as additional training on how to achieve a proper fit, trying different earplug styles and sizes for personal comfort and attenuation, or making changes within the work environment. This altered approach focuses on preventing hearing loss before it occurs.

Make it personal

A defining aspect of successful hearing loss prevention programs is personalization. One-on-one, face-to-face instruction is proven more effective than videos or reading material for training workers on proper earplug insertion, fit and overall use.7 One-on-one fit testing is also integral to measuring – rather than guessing – the level of attenuation achieved by an individual’s HPDs. In fact, personal fit testing is an OSHA best practice.

In a Best Practice Bulletin by the National Hearing Conservation Association and OSHA, “Studies have suggested that when individuals are involved in the fitting process and receive positive feedback on the proper fit of their earplug, they will be more likely to have a positive attitude about protecting their hearing and will be more apt to use hearing protection correctly and consistently in the workplace. The positive outcome should result in reducing noise-induced hearing loss in the workplace.”8

The best hearing protector is the one that is worn most comfortably by an individual, and is worn correctly 100% of the time when he or she is exposed to noise. Enable the proper selection of earplugs by offering various styles and sizes, monitoring sound exposures and protection levels regularly, and training workers individually on how to achieve a personal fit for the greatest attenuation.

While the hearing protection devices you provide may deliver high NRRs and high quality, noncompliance, improper fit and a reliance on lagging indicators all play a role in America’s ongoing struggle to adequately protect workers’ invaluable sense of hearing. By focusing on leading indicators and taking a personal approach to hearing loss prevention, we can help reduce the staggering number of workers affected by NIHL. That’s a sound solution that workers, their families, friends and employers can all agree on.