Currency

November 22, 2018

Industrial manufacturing operations have long recognized the benefits of recycling as a way to reduce their solid waste streams. And many have gotten quite good at recycling primary commodities such as cardboard, paper, plastic and aluminum.

To get to a higher level of waste diversion and potentially reach zero waste, businesses are looking more and more at recycling nontraditional or secondary commodities.

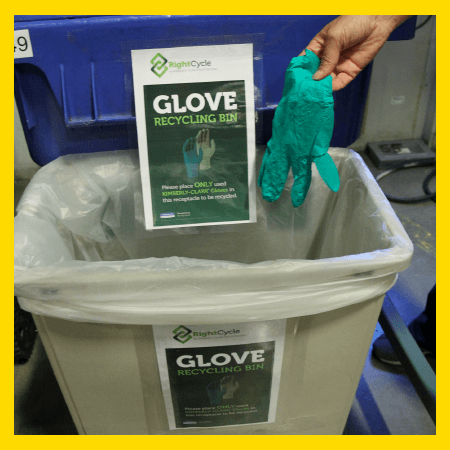

One relatively new form of recycling in this category is glove and apparel recycling. Several years ago, Kimberly-Clark Professional recognized the need for a way to divert these single-use products from the landfill. In 2011, we launched The RightCycle Program, a large-scale recycling effort for non-hazardous lab and cleanroom waste. Beginning with a handful of companies, the program collected just under two tons of materials that first year.

Five years later, it was expanded to include companies with industrial manufacturing operations. Today, it has more than 300 participants and has diverted more than 600 tons of waste that would otherwise have been landfilled or incinerated. Its future goal is to double the number of participants and quadruple the amount of waste diverted each year.

The RightCycle Program enables companies to recycle thin mil nitrile gloves, apparel (including accessories such as hoods, masks, shoe covers and other items), safety eyewear, and 100% polypropylene wipers. To qualify for the program, the items must be free of hazardous materials, biohazards and wet food.

As a rule of thumb, if these types of personal protective equipment (PPE) are being disposed of as regular trash, they should be acceptable for the program. The items are then sent to recyclers in the United States and turned into plastic pellets that are used to create durable consumer goods such as flowerpots and lawn furniture.

“By recycling rather than discarding nitrile gloves, safety eyewear and single-use apparel, companies can divert these hard-to-recycle waste streams from the landfill and get one step closer to achieving their zero waste goals,” explains Jennifer Shaffer, scientific manager, The RightCycle Program, Kimberly-Clark Professional.

How It Started Kimberly-Clark Professional provides a range of single-use products to pharmaceutical and research laboratories, offering protection from hazards within the lab as well as help to achieve or exceed their sustainability goals. A large portion of the pharmaceutical and research labs’ waste stream—up to 30%—consisted of single-use gloves and apparel.

“These difficult-to-recycle waste streams were priorities for them, but they weren’t quite sure how to manage it themselves and were seeking our help,” Shaffer says. “So, we asked ourselves, ‘How do we keep these items out of landfills and prevent them from being waste in the first place? Can we repurpose this material so we can extend its life after it is used by the lab?’”

The answer was yes. We began with the scientific labs, a small, niche business, and listened to their concerns about their existing waste streams, as well as how to ensure that their research would not be affected and their teams could get behind the recycling effort. Nitrile gloves, in particular, are a challenging waste stream to recycle.

In creating The RightCycle Program, we leveraged the expertise and knowledge of our global sustainability team in recycling materials from manufacturing facilities around the world. Their global perspective helped ensure that the recycling program would address companies’ business needs as well as their sustainability goals. To develop the program, we partnered with recycling companies that were already helping us with our own manufacturing waste, capitalizing on those partnerships to accelerate speed-to-market.

Helping Businesses Divert Waste

Lundberg Family Farms, an organic food producer in Richvale, Calif., credits the recycling program with helping it achieve a Platinum Zero Waste Facility Certification from the U.S. Zero Waste Business Council. Gloves had previously represented about 15% of the company’s landfill waste. In just a few months, Lundberg Family Farms recycled close to one ton of nitrile gloves. Now, the company diverts four tons of glove waste annually.

To get to a higher level of waste diversion and potentially reach zero waste, businesses are looking more and more at recycling nontraditional or secondary commodities.

One relatively new form of recycling in this category is glove and apparel recycling. Several years ago, Kimberly-Clark Professional recognized the need for a way to divert these single-use products from the landfill. In 2011, we launched The RightCycle Program, a large-scale recycling effort for non-hazardous lab and cleanroom waste. Beginning with a handful of companies, the program collected just under two tons of materials that first year.

Five years later, it was expanded to include companies with industrial manufacturing operations. Today, it has more than 300 participants and has diverted more than 600 tons of waste that would otherwise have been landfilled or incinerated. Its future goal is to double the number of participants and quadruple the amount of waste diverted each year.

The RightCycle Program enables companies to recycle thin mil nitrile gloves, apparel (including accessories such as hoods, masks, shoe covers and other items), safety eyewear, and 100% polypropylene wipers. To qualify for the program, the items must be free of hazardous materials, biohazards and wet food.

As a rule of thumb, if these types of personal protective equipment (PPE) are being disposed of as regular trash, they should be acceptable for the program. The items are then sent to recyclers in the United States and turned into plastic pellets that are used to create durable consumer goods such as flowerpots and lawn furniture.

“By recycling rather than discarding nitrile gloves, safety eyewear and single-use apparel, companies can divert these hard-to-recycle waste streams from the landfill and get one step closer to achieving their zero waste goals,” explains Jennifer Shaffer, scientific manager, The RightCycle Program, Kimberly-Clark Professional.

How It Started

How It Started Kimberly-Clark Professional provides a range of single-use products to pharmaceutical and research laboratories, offering protection from hazards within the lab as well as help to achieve or exceed their sustainability goals. A large portion of the pharmaceutical and research labs’ waste stream—up to 30%—consisted of single-use gloves and apparel.

“These difficult-to-recycle waste streams were priorities for them, but they weren’t quite sure how to manage it themselves and were seeking our help,” Shaffer says. “So, we asked ourselves, ‘How do we keep these items out of landfills and prevent them from being waste in the first place? Can we repurpose this material so we can extend its life after it is used by the lab?’”

The answer was yes. We began with the scientific labs, a small, niche business, and listened to their concerns about their existing waste streams, as well as how to ensure that their research would not be affected and their teams could get behind the recycling effort. Nitrile gloves, in particular, are a challenging waste stream to recycle.

In creating The RightCycle Program, we leveraged the expertise and knowledge of our global sustainability team in recycling materials from manufacturing facilities around the world. Their global perspective helped ensure that the recycling program would address companies’ business needs as well as their sustainability goals. To develop the program, we partnered with recycling companies that were already helping us with our own manufacturing waste, capitalizing on those partnerships to accelerate speed-to-market.

Helping Businesses Divert Waste

Lundberg Family Farms, an organic food producer in Richvale, Calif., credits the recycling program with helping it achieve a Platinum Zero Waste Facility Certification from the U.S. Zero Waste Business Council. Gloves had previously represented about 15% of the company’s landfill waste. In just a few months, Lundberg Family Farms recycled close to one ton of nitrile gloves. Now, the company diverts four tons of glove waste annually.