Currency

June 21, 2018

here's more to high-visibility safety apparel than meets the eye. By definition, it's clothing with highly reflective properties that help workers stay visible against any background and in any lighting conditions, even at night. The ability to be seen is critical for worker safety, especially for those working around moving vehicles and equipment—from construction sites to roadways, and in warehouses.

But not all high-visibility garments are the same, and requirements vary across the wide range of uses and environments workers face every day. The following is a handy primer on selecting the right high-visibility products for your organization and job functions.

When working in or around heavy foliage, orange or red apparel options may be preferable. The color of work zone equipment can also influence the best choice of fluorescent background materials. (West Chester Protective Gear photo)Many workers are either required or choose to wear high-visibility apparel to reduce the incidence of on-the-job accidents and injuries. These include highway and railway crews, airport workers, loggers, hunters, commercial fishermen, construction tradespeople, trash and recycling collectors, landscaping professionals, warehouse workers, first responders, and many others.

The key is to choose the high-visibility option that provides the greatest degree of contrast between a worker's body and his or her surroundings. Hunting laws in many states, for instance, require hunters to wear blaze orange garments to distinguish them from game animals. When working in or around heavy foliage, orange or red apparel options may be preferable. The color of work zone equipment also can influence the best choice of fluorescent background materials.

The federal mandate that requires select workers to wear high-visibility apparel can be found in the Manual on Uniform Traffic Control Devices 2009 (MUTCD 2009), which is translated and enforced by each state. The Occupational Safety and Health Administration also has developed an interpretation statement regarding MUCTD, intended to clarify when high-visibility apparel is required. It can be found at: https://www.osha.gov/laws-regs/standardinterpretations/2009-08-05

OSHA has essentially interpreted MUTCD 2009 to require employees working on highway and road construction work zones to wear high-visibility garments when they work as flaggers or when they are exposed to public vehicle traffic and/or construction equipment.

Other classes of occupational workers, such as trash collectors or commercial construction pros, are not required to wear high-visibility safety apparel by federal law. But the American National Standards Institute (ANSI) has established high-visibility standards to help employers and safety managers across these occupations choose high-visibility clothing that is appropriate for the safety of their workers.

Fluorescent materials that use special pigments that are brighter than other colors and enhance daytime visibility, especially in low light such as cloud cover, dusk, and dawn. Fluorescent lime, orange, and red are the three approved background color options for high-visibility clothing.

Retroreflective tape that reflects light in the direction of its source, such as a vehicle’s headlights, thereby illuminating a worker in low light or at night.

Combined performance materials, such as tape that is retroreflective and also fluorescent.

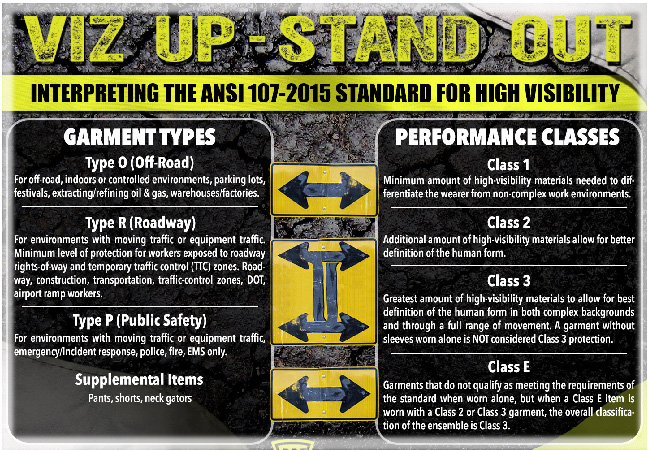

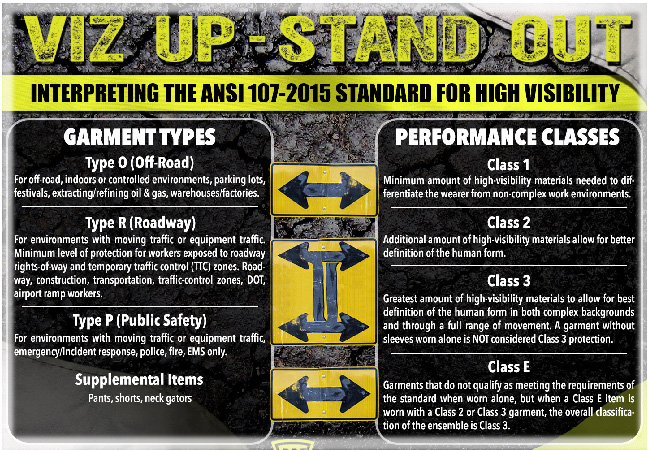

When it comes to high-visibility clothing, there are many options. With different color-ways, reflective tape patterns, sleeve lengths, it can be tricky choosing the right apparel for the job. The ANSI/ISEA 107-2015 standard, which is voluntary, sets forth what is an approved fluorescent material and reflective tape, as well as what level of brightness and coverage are recommended for various kinds of work environments.

But not all high-visibility garments are the same, and requirements vary across the wide range of uses and environments workers face every day. The following is a handy primer on selecting the right high-visibility products for your organization and job functions.

WHO wears high-visibility apparel?

When working in or around heavy foliage, orange or red apparel options may be preferable. The color of work zone equipment can also influence the best choice of fluorescent background materials. (West Chester Protective Gear photo)Many workers are either required or choose to wear high-visibility apparel to reduce the incidence of on-the-job accidents and injuries. These include highway and railway crews, airport workers, loggers, hunters, commercial fishermen, construction tradespeople, trash and recycling collectors, landscaping professionals, warehouse workers, first responders, and many others.

The key is to choose the high-visibility option that provides the greatest degree of contrast between a worker's body and his or her surroundings. Hunting laws in many states, for instance, require hunters to wear blaze orange garments to distinguish them from game animals. When working in or around heavy foliage, orange or red apparel options may be preferable. The color of work zone equipment also can influence the best choice of fluorescent background materials.

WHEN is high-visibility apparel required?

The federal mandate that requires select workers to wear high-visibility apparel can be found in the Manual on Uniform Traffic Control Devices 2009 (MUTCD 2009), which is translated and enforced by each state. The Occupational Safety and Health Administration also has developed an interpretation statement regarding MUCTD, intended to clarify when high-visibility apparel is required. It can be found at: https://www.osha.gov/laws-regs/standardinterpretations/2009-08-05

OSHA has essentially interpreted MUTCD 2009 to require employees working on highway and road construction work zones to wear high-visibility garments when they work as flaggers or when they are exposed to public vehicle traffic and/or construction equipment.

Other classes of occupational workers, such as trash collectors or commercial construction pros, are not required to wear high-visibility safety apparel by federal law. But the American National Standards Institute (ANSI) has established high-visibility standards to help employers and safety managers across these occupations choose high-visibility clothing that is appropriate for the safety of their workers.

WHAT are the basics of high-visibility apparel design?

The typical components of most high-visibility garments include:

WHAT are Performance Class and Garment Type designations, and how do they impact product selection?

When it comes to high-visibility clothing, there are many options. With different color-ways, reflective tape patterns, sleeve lengths, it can be tricky choosing the right apparel for the job. The ANSI/ISEA 107-2015 standard, which is voluntary, sets forth what is an approved fluorescent material and reflective tape, as well as what level of brightness and coverage are recommended for various kinds of work environments.